In synthetic ammonia system, large amounts of methane and hydrogen in tower vent gas and reservoir purge gas were directly sent into three wastes boiler. However, only the heat energy was recovered with a poor economy. Nevertheless, if methane was separated from the tail gas as LNG while separated hydrogen sent back to synthetic ammonia system, the additional value of products would be greatly improved.

Therefore, after extensive survey and technical research, we have designed the comprehensive utilization of synthetic ammonia tail gas technology. According to the boiling point differences between components of vent gas, methane was separated by cryogenic distillation. Meanwhile, the nitrogen-hydrogen gas with inert gases content less than 3% was obtained, which could directly be sent back to the compression section of synthetic ammonia system.

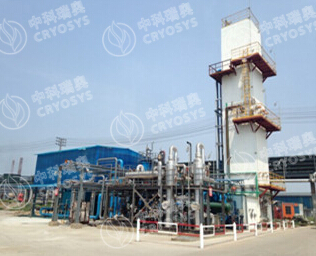

Typical Case

The “Gansu Jinchang chemical engineering Co.ltd. comprehensive utilization of synthetic ammonia tail gas for LNG” constructed by us was put into operation on October 8, 2012. The device run well and all indicators fully meet the expected requirements. In this project, LNG was obtained with hydrogen recycled from synthetic ammonia purge gas by purification, desiccation and cryogenic liquefaction and separation. By the realization of energy saving and emission reduction, a remarkable economic benefits for the enterprise were increased.